EDF and Pyrocontrole: a partnership for the future

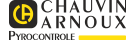

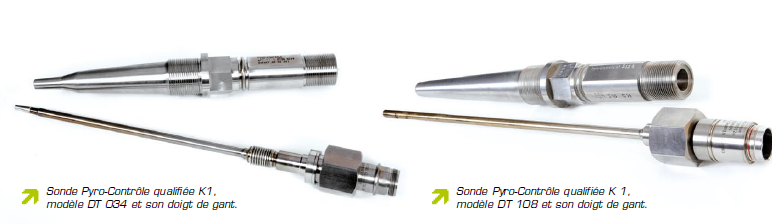

K1 and K3-qualified Pyrocontrole temperature sensors will equip the future Flamanville 3 EPR nuclear reactor. Since the 1970s, Pyrocontrole has been acknowledged by contractors and users as offering high performance in the field of qualified temperature probes for the nuclear industry.

K1 and K3-qualified Pyrocontrole temperature sensors will equip the future Flamanville 3 EPR nuclear reactor. Since the 1970s, Pyrocontrole has been acknowledged by contractors and users as offering high performance in the field of qualified temperature probes for the nuclear industry.

Today at Pyrocontrole, they have built up considerable know-how regarding these products as they are constantly faced with the difficulties inherent to this range of highly technical products. The numerous safety constraints are liable to evolve and the best possible level must always be achieved.

The commercial and technical follow-up needs to be particularly effective because the implications for the contractors are strategic: Pyrocontrole's temperature sensors help to ensure that our customers' nuclear reactors operate correctly, so they have to function without fail!

To maintain the demanding level required, you need complete control of the qualification, production and control processes. The documentary structure, traceability of the procurements and manufacturing and inspection operations, and the stability of our teams are key elements in our industrial policy.

"Nuclear safety" comprises all the steps taken at all stages, from design, manufacture of the equipment, nuclear plant construction and operation to the definitive shutdown of an installation. The purpose of this is to ensure safe operation, anticipate incidents and limit their effects. The concept of safety is a fundamental element in the requirements covering our temperature sensors for nuclear environments. There is a genuine culture of safety. This safety concept is structured according to several points.

1 – All the personnel involved in producing "nuclear-qualified products" must be made aware of the "nuclear safety" aspects.

2 – The design must respect the required construction rules: RCCE and RCCM codes.

3 – Some purchasing or manufacturing operations are identified as ACQ (Action Concerning Quality) and are the subject of highly-formalized monitoring.

Qualification of the equipment is a crucial preliminary process. The goal of qualification campaign is to test the equipment's behaviour during an accident (e.g. earthquake) after first artificially ageing the equipment. "Qualification Summaries" are then drafted after these qualification campaigns.

The "Reference File" describes the precise conditions for production of the equipment covered by the qualification campaigns. Any equipment delivered subsequently must be traceable to this "Reference File". There are 4 levels of qualification : K1, K2, K3 and NC (from the lowest to the highest).

Did you know ?

EPR technology

EDF has begun building a third production unit on the Flamanville site which will be an EPR (European Pressurized Reactor) using pressurized water.