Temperature MEASUREMENT and TESTING

Comprehensive range of rugged, reliable measurement solutions for severe environments

Pour les températures élevées et les conditions extrêmes rencontrées en métallurgie, fonderie et sidérurgie, Pyrocontrole propose des instruments fiables et résistants adaptés à ces environnements sévères :

- Capteurs de température pour des tests fiables

- Régulateurs de puissance pour optimiser les réglages de température

- Enregistreurs numériques pour la cartographie des fours

- Automatisation - HM Ipour visualiser tous les processus industriels

Temperature sensors

Des solutions robustes et fiables

Pyrocontrole propose un choix de capteurs de température adaptés équipés de protections spécifiques pour correspondre à votre application. Des protections métalliques, céramiques ou composites rendent les ensembles de température plus résistants et prolongent la durée de vie des capteurs.

Exemples d'applications :

- Fonderie

- Fer et acier

- Métallurgie

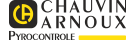

Mesure de température dans les bains de fusion et les bains de maintien.

>Applications : bains de fusion et de maintien, mesure de température dans les fours de trempe et de recuit et de stabilisation • Ensemble de température portable Mesure ou contrôle avec un ensemble de mesure équipé d'une poignée.

• Ensemble de température fixe et/ou mobile

Mesure de contrôle du bain avec unensemble de températurecoudé fixe et/ou amovible, afin d'éviter de casser le protecteur lorsque le four est chargé de lingots d'alliage d'aluminium.

• Ensemble à température fixe

Mesure de contrôle du bain avec ensemble de température droit fixé dans le réfractaire, à gradient thermique connu.

![]() Télécharger l'

Télécharger l'

étude de cas - Solutions de mesure pour la fonderie d'aluminium

- Fer et acier

Qualifiée pour résister aux hautes températures, notre offre d'ensembles de température permet de mesurer très précisément les températures, améliorant ainsi la qualité de vos produits et la sécurité de vos process.

> Applications : fours de trempe, fours de recuit et de stabilisation

• Capteurs à dôme

• Capteurs à dôme

Dans des environnements sévères, ces ensembles permettent de contrôler la température du dôme et d'optimiser la gestion de l'énergie utilisée.

Ils ont une durée de vie particulièrement longue car leur protection les rend particulièrement robustes.

• Capteurs de fond

• Capteurs de fond

Précis et résistants, ces assemblages sont insérés dans le réfractaire avec ou sans saillie, ces assemblages surveillent la température et assurent la sécurité du process.

• Capteurs Cadid

• Capteurs Cadid

Soumis à des contraintes de température, l'élément sensible de ces capteurs est protégé par une gaine constituée d'un matériau adapté à l'environnement attendu.

Qualifiée pour résister aux hautes températures, notre offre d'ensembles de température permet de mesurer des températures de manière particulièrement précise, améliorant ainsi la qualité de vos produits et la sécurité de vos process.

> Exemple d'application: hauts fourneaux

• Ensemble de température de paroi

Installé dans le réfractaire de la cuve du four, cet ensemble de température surveille la température de l'installation et permet de garantir la sécurité du procédé.

• Ensemble de prise de température de soufflage

Positionné sur les sorties vent chaud, il mesure la température des fumées.

• Ensemble température de sortie du poêle Cowper

En position d'immersion, cet ensemble température peut être utilisé pour mesurer la température de l'air chaud en sortie d'un poêle Cowper. Ceci est essentiel pour assurer un rendement satisfaisant du four. Cet ensemble bénéficie d'une tenue à haute température et est équipé d'une tête de raccordement spécifique pouvant résister aux sollicitations mécaniques et aux chocs.

• Ensemble de température de processus standard

Selon l'endroit où il est monté, il peut être utilisé pour surveiller la température de l'huile de refroidissement ou de l'eau de refroidissement.

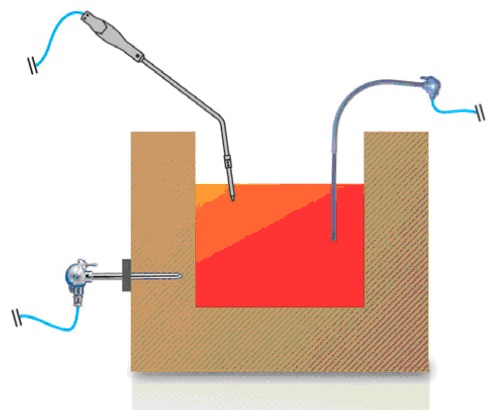

Power controllers

Économiser l'énergie

Les systèmes de contrôle sont essentiels pour optimiser la température. Equipés d'une technologie de pointe, les contrôleurs de puissance Thyritop 40 et Thyritop 30 sont idéaux pour les besoins des professionnels.

Avantages :

- limitation et optimisation de la puissance de chauffage,

- surveillance de la charge,

- multiples possibilités de contrôle et de supervision.

• Contrôleurs de puissance Thyritop 400

Ces contrôleurs de puissance communicants contrôlent toutes les charges résistives et inductives pour le chauffage électrique. Disponible en 3 versions, de 37 A à 2 900 A, il offre précision, flexibilité et une conception robuste pour contrôler vos éléments chauffants.

>Applications

>Applications

Ces contrôleurs sont particulièrement adaptés pour :

les fours continus les fours

multizones

• Régulateurs de puissance Thyritop 30

Les régulateurs de puissance Thyritop 30 sont idéaux pour les besoins de contrôle de puissance électrique les plus fréquents. Simples d'utilisation et particulièrement robustes, ils offrent une solution de contrôle de puissance à faible coût.

>Applications

>Applications

Ces contrôleurs sont particulièrement adaptés pour : les

fours de trempe

Téléchargez notre brochure Contrôleurs de puissance

Téléchargez notre brochure Contrôleurs de puissance

Digital recorders

La précision et l'homogénéité de la température de maintien du four sont deux caractéristiques cruciales pour la qualité et le coût du traitement thermique obtenu. Pour vérifier l'homogénéité de la température d'un four, l'enregistreur numérique PYROTRACER est l'outil idéal.

Applications : fours de trempe

Spécifiquement conçu pour une configuration et une mise en œuvre rapides et simples, cet enregistreur sans papier « plug & play » permet de contrôler la température en temps réel et d'enregistrer jusqu'à 18 canaux de mesure. La sécurité de cet enregistrement « QUALITE » est assurée au moyen de fichiers cryptés et infalsifiables.

_ Écran "TFT" extra-haute définition 6,4 pouces

_ Écran "TFT" extra-haute définition 6,4 pouces

- 256 couleurs

_ Jusqu'à 18 canaux de mesure isolés les uns des autres

_ Sauvegardes des données sur mémoire Compact Flash jusqu'à 2 Go

_ Conforme 21 CFR part 11

_ Livré en standard : Ethernet lien + logiciel de traitement PC

![]() Télécharger la

Télécharger la

plaquette de présentation

Enregistreurs graphiques

Ces enregistreurs de données avec écrans tactiles sont des solutions idéales pour l'acquisition de données et l'analyse de processus dans toutes les industries. Spécialement conçue pour une utilisation plus simple, cette nouvelle génération d'enregistreurs graphiques CA 6500 contribue à rendre votre travail nettement plus simple et surtout plus efficace !

• Vitesse d'enregistrement plus rapide

• Sécurité des données renforcée

• Affichage personnalisable des données et graphiques

• Utilisation intuitive avec écran tactile

• Plusieurs canaux d'enregistrement

• Données accessibles sur site et/ou à distance grâce aux outils de gestion

Des atouts majeurs pour des résultats optimaux sur le terrain !

Adaptés à tous types d'applications, ces instruments sont capables de gérer jusqu'à 72 canaux d'enregistrement

Avec plusieurs types d'entrées :

Thermocouples, RTD, Cu10, Cu50, Cu100, Ni100, Ni200, Ni500, Ni1000, Universel : mA, V, mV

![]() Télécharger

Télécharger

la brochure CA 6500

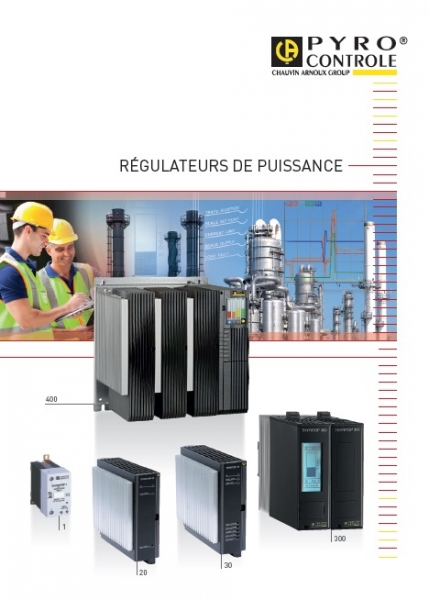

Automation - HMI

CPS Touch® solution

nouvelle génération adapté pour répondre aux exigences industrielles de supervision de processus dans la métallurgie, foundrywork et le secteur de la sidérurgie.

De l'enregistrement des données au contrôle des machines, la nouvelle gamme d'interfaces homme-machine tactiles CPS Touch ® offre de multiples avantages. Composée de 5 modèles, du plus simple au plus sophistiqué, la gamme CPS Touch® s'adapte à tout besoin de supervision.

> Applications : mélangeurs, fours, etc.

- CPS Touch® :  - Choix de 5 modèles de 4,3 à 15 pouces

- Choix de 5 modèles de 4,3 à 15 pouces

- Écran tactile avec plus de 65 000 couleurs

- Logiciel de programmation haute performance CPS Studio

- Accès protégé : neuf niveaux de sécurité par utilisateur

- Conforme 21 CFR part 11

- Robuste IP65 et protection IP66 K disponibles en option

- Bibliothèque d'objets prêts à l'emploi

- Télécommande![]() - Compatible avec une large gamme d'interfaces de communication

- Compatible avec une large gamme d'interfaces de communication

Accompagnement

En fonction de vos besoins, partenaire à vos côtés, Pyrocontrole vous propose :

- Des formations sur les produits de la gamme CPS Touch® (formation professionnelle certifiante)

- Le développement d'applications spécifiques selon votre cahier des charges

![]() Télécharger le

Télécharger le

« CPS Touch® brochure » vidéo CPS Touch®: centralisée, contrôle du bout des doigts de vos processus![]()