Calibration: equipment and services

Guarantee the performance of your thermal installation and optimize your energy consumption: calibration equipment and services.

Lorsqu'ils sont utilisés régulièrement, la précision même des meilleurs instruments de mesure se détériore. Pour contrôler les performances des instruments de mesure et éviter toute détérioration de la qualité, l'étalonnage en température est indispensable. Fortes de leur parfaite maîtrise de la chaîne de mesure de la température, les sociétés du Groupe Chauvin Arnoux Pyrocontrole et Manumesure proposent un ensemble complet de solutions d'étalonnage de température. Quel que soit le secteur industriel, Pyrocontrole et Manumesure réalisent l'étalonnage de toutes marques de capteurs et d'équipements de mesure et proposent également des équipements et systèmes d'étalonnage innovants et performants afin de vous offrir un service complet adapté à vos besoins.

Découvrez nos services d'étalonnage

Découvrez nos systèmes d'étalonnage et d' équipements

- capteurs de référence standard

- capteur avec étalonnage in situ

- Cellules à point fixe

- fours d' étalonnage

- étalonnage des capteurs de surface

CALIBRATION SERVICES

REFERENCE TEMPERATURE SENSORS

Que vous ayez besoin d' étalons de travail ou d' étalons de référence , nous possédons des équipements performants nous permettant de fabriquer des étalons de référence de température spécifiques pour l'étalonnage par comparaison de vos capteurs à résistance et thermocouples.

Besoin d'un conseil? Nos spécialistes en métrologie sont là pour vous guider, étape par étape.

Etalons de travail

Utilisés dans les ateliers et laboratoires, les capteurs de référence permettent un étalonnage de premier niveau. Ils doivent être recalibrés régulièrement par rapport à un étalon de référence.

Capteur Pt100

• Gammes : -100°C à +450°C et -100°C à + 550°C

• Résistance à 0°C : 100 Ω

• Stabilité jusqu'à 0,05°C

• Courant de mesure : 1 mA

• Diamètre et longueur de partie sensible : 6 x 450 mm

• Classe d'interchangeabilité : Classe A selon IEC 751

• Boîtier disponible en option

Thermocouples de type S : modèle S90-03

•Plages : 0 °C à + 1 554 °C

• Dimensions : 7 mm x 650 mm

• Matières : 10% platine rhodium / platine pur

• Certificat d'étalonnage par comparaison

• Livré en coffret

♦ Etalons de référence

♦ Etalons de référence

Utilisés comme étalons de référence dans les laboratoires et les services de métrologie.

Sonde Pt100

• Gammes : -100°C à +450°C

• Stabilité jusqu'à 0,05°C

• Résistance à 0°C : 100 Ω

• Courant de mesure : 1 mA

• Diamètre et longueur de la partie sensible : 6 x 450 mm

• Classe d'interchangeabilité : Classe A selon IEC 751

• Certificat d'étalonnage par comparaison.

• Livré en étui

Thermocouples S : modèle LNE S80

• Gammes : 0 °C à + 1 554 °C

• Fabriqués sous licence LNE

• Dimensions : 7 mm x 650 mm

• Matières : 10% platine rhodium / platine pur

• Certificat d'étalonnage par comparaison

• Livré dans un Cas

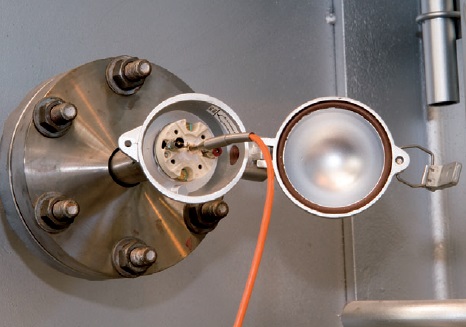

SENSOR WITH IN-SITU CALIBRATION

Économisez de l'énergie : choisissez des capteurs avec étalonnage in-situ !  Si vous utilisez des capteurs avec étalonnage in-situ, il est possible de contrôler la température sans retirer le capteur et sans arrêter le processus. Le principe est simple : sur le montage de température, un espace est prévu pour insérer une sonde étalon pour un étalonnage in-situ par comparaison. Cela permet d'économiser de l'énergie tout en augmentant la productivité et la qualité.

Si vous utilisez des capteurs avec étalonnage in-situ, il est possible de contrôler la température sans retirer le capteur et sans arrêter le processus. Le principe est simple : sur le montage de température, un espace est prévu pour insérer une sonde étalon pour un étalonnage in-situ par comparaison. Cela permet d'économiser de l'énergie tout en augmentant la productivité et la qualité.

Applications

Méthode brevetée (brevet n° 0213616) qui peut être utilisée pour tous types d'appareils de mesure de température, qu'il s'agisse de thermocouples ou de sondes à résistance en platine.

Ce type de capteur est très largement utilisé dans les fours industriels et la pétrochimie.

> Avantages des capteurs à étalonnage in-situ :

- Evite la surchauffe : économise de l'énergie

_ Gain de temps : étalonnage de la température effectué directement sur site

- Pas besoin de retirer le capteur

- Pas besoin d'arrêter le process

- Fréquence d'étalonnage selon vos besoins.